The War Garden Victorious

Victory Edition 1919 HOME CANNING & DRYING of Vegetables &

Fruits

HOME CANNING MANUAL

|

|

|

HIGH ALTITUDES At high altitudes the boiling point of water is below 212° F. At moderate elevations satisfactory results may be obtained in the use of the hot-water bath by increasing the time of sterilization 10 per cent for every 500 feet above 1000. To insure best results in very high altitudes, however, a steam pressure canner or aluminum pressure cooker is recommended to be used. This type of canner produces a temperature up to 250 ° F. at 15 lbs. pressure, insuring proper sterilization and also saving time and fuel. A steam pressure canner may be bought around $20. Several families may use one, and divide the cost.

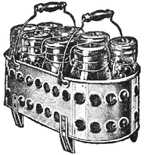

Fig. 7. Home canner and steam cooker holding 14 quart jars. Requires same time as hot-water bath. OPERATION OF PRESSURE CANNERS AND ALUMINUM COOKERS 1. Have water in the canner up to the false bottom, but not above it.

Keep this water boiling during the time that packed jars are being placed in the

canner, and add water occasionally to prevent its boiling dry. |

CONTAINERS For home use glass jars are more satisfactory for canning than tin. This

is especially true this year when there is a shortage of tin cans. Tin cans are used

chiefly for canning on a large scale for commercial purposes.

TESTS FOR JARS Jars should be tested before they are used. Some of the important tests are here given: 1. Glass-top Jars.––First examine for cracks. Then run a finger around the edge of necks of jars, and if there are sharp projections, file them off, or scrape them off with an old knife. If left on they may cut rubbers and interfere with perfect sealing. Place a top on a jar. It will slip from side to side, but should not rock, when tapped. Rocking tops will not make a tight seal. Sometimes the fault is with the top and sometimes with the neck. Defective jars and tops when discarded for canning purposes may be used as containers for jams, etc. The top-bail should go into position with a light snap. If too loose it should be taken off and bent slightly inward in the center. If too tight bend outward |